Hydroponics System Types

NFT - NutrientFilmTechnique

NFT uses gutters, channels or pipes in which a water

film is created on the ground. With this method, the plants get a

very good water-air mixture. NFT systems operate continuously with

a pipe gradient of ~ 3%/m.

In order to place the plants, they are either fixed directly in

the rectangular channel in the stone wool cube, or using mesh

baskets and foam inserts. For longer systems, it is advisable to

set several feeds to counteract a nutrient deficit. Oxygen

enrichment in the tank is helpful here, although not absolutely

necessary.

DWC - DeepWaterCulture

Hydroponics in ponds was already known over 2000

years ago and was optimized by the Maya's. However, this fell

under aquaponics and is explained in more detail in "Tips &

Info's".

In DWC systems, the plants are permanently in the water and can

only develop aerial roots to a limited extent. This inevitably

leads to root rot and the death of the plants.

This is counteracted with air stones and air compressors. As in

the aquarium, the water is enriched with sufficient oxygen in this

way and thus complements all the needs of the plants.

Kratki

Kratki is an derivative of the DWC systems and was

developed by Bernard A. Kratky in 1996.

It is a purely passive system without any circulation.

Basically any form of container can be used for this purpose.

The larger the plant will grow, the larger the container must be

chosen.

The container is filled with the nutrient solution up to the mesh

basket, the pH value is adjusted and nature is allowed to take its

course.

No further maintenance is necessary with this system. However, the

growth rate is comparable to that of pure agricultural crops.

Aeroponik

As already announced in the headline, aeroponics is

the premier class of hydroponics. Unfortunately, in addition to

the complex technology, it is also very maintenance-intensive. The

nutrient solution is sprayed on in cycles via spray nozzles. This

is where the big problem lies. The nozzles can quickly become

blocked, not cover some areas or leaks can paralyze the entire

system.

The advantage of these systems, however, is the possibility of

also growing roots and tubers.

In the event of a power failure, the complete assembly is also

history in a short time.

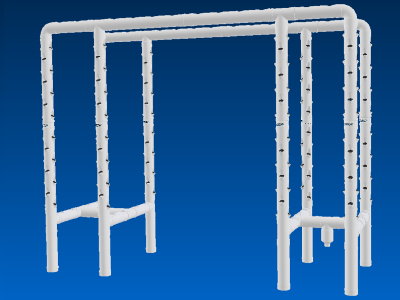

VGT - VerticalGrowTower

An absolute favorite when it comes to plant density.

Due to the vertical structure, more than 500 plants/m² are

possible (of course with smaller plants).

With a VGT system, you can easily supply an entire family in one

square metre.

The basic system consists of vertical tubes in which pockets are

formed. The nutrient solution is pumped up from the tank and rains

down from there in the tube.

The noise level is like a light rain or indoor fountain and only

runs in cycles.

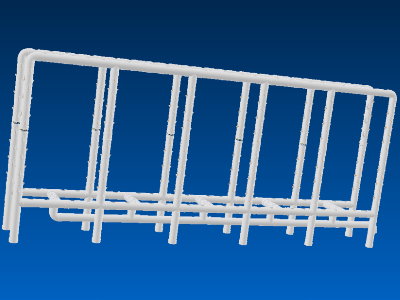

Ebb-Flow-Basin

This type of system comes very close to conventional

agricultural technology. The plant basins are filled with perlite,

clay fire balls or gravel and are located above the tank.

The pump moves the nutrient solution upwards, the water level

rises and the bell siphon triggers at the set level. As a result,

the planting tank is completely emptied again.

Instead of a bell siphon, you can also use a controlled solenoid

valve with a level sensor.

You can still dig here.

Wick System

Even if you would only consider this simple system as hydroponics to a limited extent, it is also represented here. In contrast to the structurally identical, in the pot culture for indoor plants, here no soil is used as a medium. Materials such as coconut wool are used that do not contain any nutrients of their own.

Drip System

Large plants also form large rootstocks, which can

pose a problem for other systems due to the small designs.

Dutch buckets are very suitable here for tomatoes, courgettes,

cucumbers, etc.

Mesh baskets are let into buckets with lids, a filter bag is

placed in the bucket and a collection line for the return flow is

connected.

The nutrient solution is fed in slowly and in cycles via thin feed

lines, which is returned again via the collecting line.

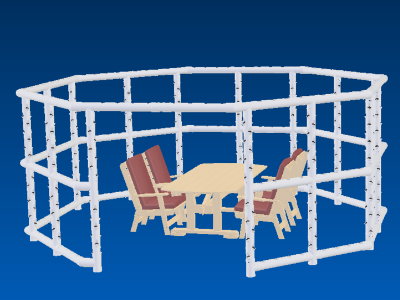

Rotating Garden

A relatively new design is the rotating drum.

Attractive and futuristic to look at, these systems have further

advantages.

The light source can be placed in the middle and by changing the

gravity, the plants grow more special cells that make them more

stable and stronger.

In addition to a large planting density, these systems are real

eye-catchers.

Microgreens

Misjudged little pupils...

Probably the easiest, cheapest and fastest way to

get fresh vegetables is microgreens.

All you need is a spray bottle, a flat container, a simple

medium such as a fine grid or a perforated plastic insert, and

the diluted nutrient solution.

What are microgreens?

Microgreens are young plants that are harvested

immediately after real leaves develop. They are used as dietary

supplements, as visual enhancements, and to improve taste and

texture. Microgreens are used to add sweetness and spiciness to

foods. Microgreens are also to be seen as additional food

because they contain an extremely large number of vitamins,

fiber and minerals.

Pea microgreens have a lot of protein and provide the body with

all the important amino acids. They are characterized by rapid

germination and their fine taste is reminiscent of young peas.

Radish seedlings taste fresh and at the same time have a spicy

note.

Which microgreens are there?

Amaranth, Asian lettuce, basil, cauliflower, beans, broccoli, watercress, buckwheat, chia, dill, peas, fennel, chervil, coriander, cress, chard, mint, mizuna, carrots, pak choi, quinoa, radishes, rocket, Brussels sprouts , beetroot, red cabbage, rocket, lettuce, mustard, sunflower, wheatgrass. Depending on the variety, microgreens are ready to harvest between one and three weeks. All you need is a sharp knife and a steady hand.

Various information can be found in the download area.