Hydrogrow Services

Product Development

Hydroponic systems are inherently very simple and

there is a lot of scope for design.

Through the connection to TES - TechnologyEngineeringServices,

ideas are put into practice.

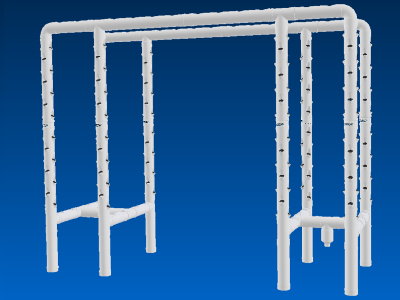

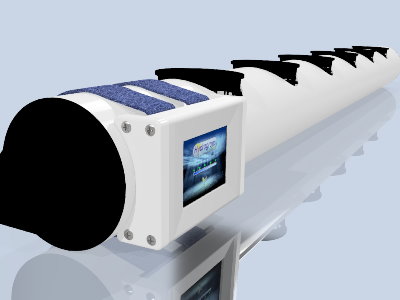

The product development takes place in CAD with photorealistic

images in advance. After the technical development, the first

prototype is created from milled parts, thermoforming, 3D printing

and purchased parts. Depending on the type of system, injection

molds can be made, which makes mass production easier.

In addition to the mechanics and electrics, digital controls can

also be developed customer-specifically in this way.

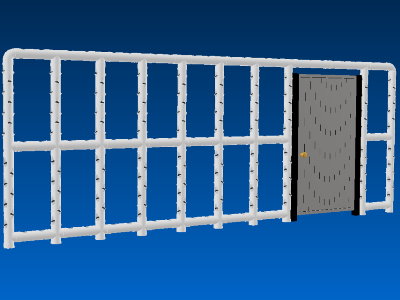

Custom-Made Products

Where there is little space, good planning is also

necessary. Even a small balcony, in the porch or living room can

be converted into a hydro farm, and not only in a space-efficient

way, but also in an elegant way.

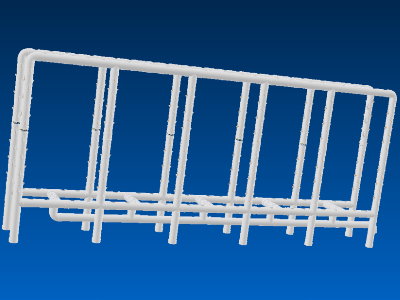

Small walls or railings are perfect for NFT systems. Places with

only one square meter can be stylishly upgraded with a VGT and the

whole family can be provided with fresh fruit and vegetables as a

"waste product".

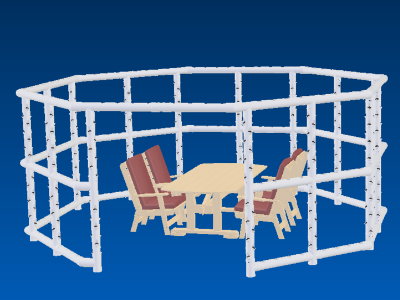

It is also possible to transform parts of terraces or gardens into

a futuristic hydro farm.

Trouble with the neighbors? A privacy screen would be nice? Go

green and use a VGT hydro wall, with which you not only separate

stylishly, but can also appease the neighbors.

Flat Roof Urban Farming

Although flat roofs are not that common in Europe,

many garages or companies are still perfect for a hydro farm.

In addition to the practical benefits of self-sufficient food

supply, these dead areas can simply be planted and turned into a

small oasis. Hydroponic systems are weatherproof, easy to clean

and require little maintenance. With a self-sufficient power

supply and customer-specific automation, the use is reduced to

planting, harvesting and enjoyment.

In-House Systems

Hydrogrow continues to research optimizations

Despite the variety of systems on the market and

their simplicity, there is still a lot of room for improvement.

Hydroponic systems do not always have to be functional, you can

also play with the design. Although tubes, whether vertical or

horizontal, serve their purpose, they are not necessarily a real

eye-catcher in restaurants, clubs or hotels.

Hydrogrow is constantly looking for new approaches and designs,

because different applications also require the right systems.

Automation, digital mixing units, recirculating tank systems and

online monitoring are just a few components that are not yet

widespread on the market or are difficult to afford.

It is important not only to promote high-end systems, but also

well-designed systems for the smaller purse.

Go Green Worldwide:

Developments focus on the different climate zones

and local conditions. Cold climates also require foldable

systems or equipment that are easy to store. Hot climate zones,

on the other hand, must include cooling and shading in order to

achieve optimal results.

Due to the global pandemic, some situations became a reality

very quickly. Supermarkets were quickly sold out as soon as a

lockdown was announced, fresh vegetables were absolutely not

available in house arrest and the space in apartments is more

than limited to counteract this with small beds or flower pots.

Self-sufficient energy supply, water storage and

self-sufficiency are already a serious issue.